Only 34 % of the companies felt well prepared for the enforcement of the Supply Chain Act.

The Supply Chain Act

The whole company needs to be on board

Good intentions aren’t enough anymore: The Supply Chain Act (LkSG) has made voluntary commitments to environmental protection and human rights in Germany a legal requirement. What are companies doing about this? And what more do they need to do to comply with the legislation?

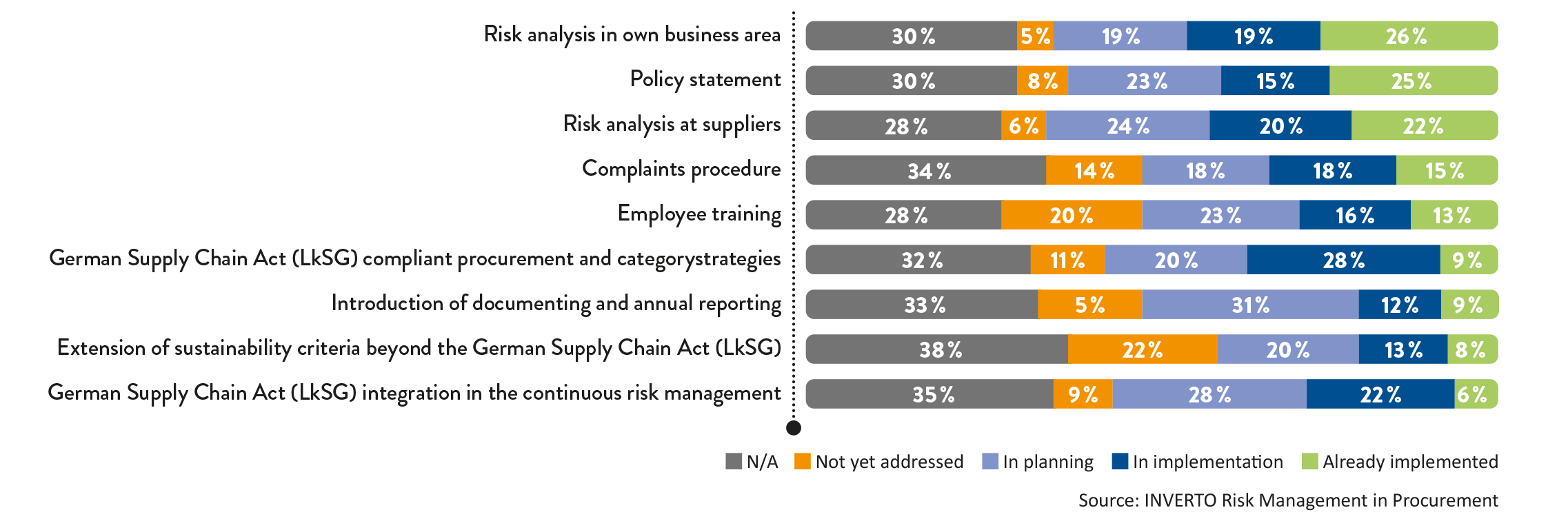

Only around a third of those surveyed as part of the Inverto Risk Management Study said they were well prepared for the new legislation – this is a rather concerning statistic given that the new legislation came into force only eight to ten weeks’ later. The significant level of uncertainty cannot be explained solely by the complexity of the challenge.

The risk analysis guidance from the Federal Office of Economics and Export Control (BAFA) was only published in August 2022, when many companies had already begun their supply chain analyses. The rules on what annual reports should look like in the future and information on adequacy, effectiveness, and complaints procedures were only published in October. In terms of content, all those we interviewed complained that the information was not entirely clear and precise.

“We started the process at the end of 2021, when it was still not clear what BAFA wanted. We were trying to hit a moving target, so it was a challenge,” said a procurement manager from a media company. And a head of procurement at a software firm was also critical: “Unfortunately, the legislation leaves so much room for interpretation that I don’t know which resources to use to implement the Supply Chain Act and be compliant with it. There’s a great deal of room for interpretation.” “We have the feeling that there are still ambiguities on the legislative side as well,” said a procurement manager at a global energy technology manufacturer, summing up his skepticism.

Time effort

Limited ability to influence suppliers

Lack of expertise

Only 34 % of the companies felt well prepared for the enforcement of the Supply Chain Act.

Managers are hopeful that digital tools will provide the solutions they need. Virtually all those who took part in the in-depth interviews described working with software to examine their complex supply networks and process the enormous quantities of data. Companies tend to use software from specialist sustainability and/or risk management providers.

“You can’t master the complexity without a digital tool to help you. That means that somewhere you need a data logger that records and compresses all the information. It has to be consolidated in such a way that I know where to look if there’s ever cause for suspicion,” explained a procurement manager and sustainability expert at an electrical equipment manufacturer. A procurement manager at a software corporation emphasized the importance of functioning interfaces: “A very simple communication platform needs to be set up, because suppliers will be asked questions about this by thousands of customers. At the same time, they must be able to provide all the information, including certificates. All of this needs to be brought together nicely and neatly on a communications platform to make the relevant information available end-to-end through these network effects.”

1. Plan in plenty of time – if you are required to comply with the Supply Chain Act from 2024, you should start preparing today!

2. Set up 3. Develop operational concepts in specialist departments, check product group strategies and supplier portfolios in critical areas. 4. Educate and train your employees 5. Invest in the right software 6. Collaborate with your suppliers and, where possible, with competitors.

Companies that made few if any sustainability efforts prior to the Supply Chain Act being adopted, saw themselves at a clear disadvantage compared to those who adopted their initial strategy a few years ago. “Environmental and human rights standards are core components of the requirements placed on our suppliers. We have always published these in the Code of Conduct for Business Partners. We have added the topics now embedded within the Supply Chain Act that we hadn’t covered previously. However, environmental and human rights standards have long been requirements in principle. We have been auditing suppliers on these for the last ten years,” explains the procurement and supply chain manager at an automotive and electronics group.

On the other hand, the legislation has been an eyeopener in many companies, forcing some of them to redefine the concept of risk: “The Supply Chain Act requires you to change your perspective you have to look at what risks we face. For the first time, we had to really understand what our supply chains look like,” explained a sustainability manager who works in the IT sector. For others, the legislation has created a need to do more than the absolute minimum, according to a process manager at an engineering company: “Our first priority is naturally to fulfil the minimum requirements. As soon as these are embedded within the company and have become part of the routine, we then want to increase transparency in the supply chain and influence the entire supply chain, i.e. steer and monitor our suppliers accordingly.” //