Decarbonization

Reduce your carbon footprint

As businesses face increasing pressure to reduce carbon footprints, procurement plays a crucial role in driving decarbonization efforts across the supply chain. Strategic decarbonization in procurement can accelerate your organization’s journey toward net-zero emissions.

How We Create Sustainable Impact

Significant impact of procurement

Procurement significantly impacts an organization’s carbon footprint, with up to 80% of emissions originating from the supply chain.

Carbon Footprint Analysis and Supplier Collaboration

Inverto is a key partner in achieving sustainable procurement goals by developing sustainable procurement strategies, analyzing carbon footprint, and collaborating with suppliers to minimize indirect emissions.

Beyond Compliance: Driving Procurement Value through Sustainability

The call for sustainable procurement is growing stronger – to protect the planet, and to secure resilience and efficiency. With our white paper Beyond Compliance, we want to highlight this shift and support companies with practical approaches.

PROCUREMENT: LET’S GET REAL!

Our expert Kiren on Decarbonization

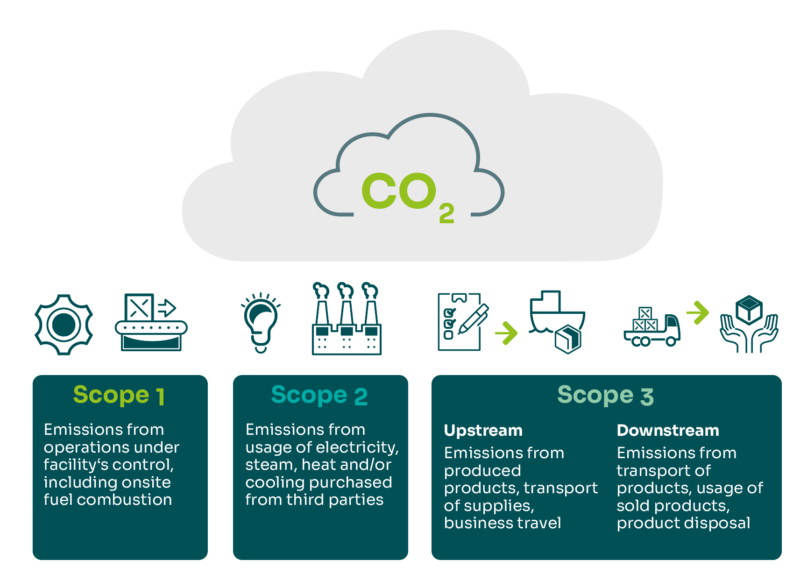

At the beginning of the decarbonization journey there is a need to create transparency across the different types of emissions:

- Scope 1: direct emissions from the company’s own production

- Scope 2: indirect emissions related to the purchasing of electricity and air conditioning for the company’s buildings

- Scope 3: all other emissions that arise in the company’s value chain, caused by suppliers, services or logistics

While the amount of Scope 1 and Scope 2 emissions is relatively easy to determine and within a company’s direct sphere of influence, Scope 3 emissions, which can be as much as 70-90% of a company’s total emissions, lack transparency and direct access. With its direct contact to suppliers and service providers, procurement plays a crucial role in mitigating Scope 3 emissions.

How we support your procurement in the decarbonization journey

- build a baseline

- understand your ESG procurement maturity

- define key abatement levers to understand where to focus.

- set decarbonization roadmap

We often do this alongside a typical cost assessment to find cost savings to fund the carbon journey – helping mitigate the challenge of investment

- Data & Tools to actively measure emissions and progress

- Upskilling procurement teams

- Refining procurement processes to factor decarbonization into decision making

Reducing emissions from suppliers

- Actively influence suppliers through incentives and disincentives

- Adapt sourcing processes to select new suppliers that have lower emissions

- Look across the value chain and at the broader ecosystem, e.g. closer collaboration with suppliers, industry alliances

Reducing emissions from the supply chain

- Define sourcing regions based on emissions, e.g. Nearshoring, Greenshoring

- Ensure compliance with regulations, e.g. CSDDD, CBAM,…

- Optimize logistics footprint, e.g. switching from air freight to sea freight, or moving from diesel vans to EVs

Reducing emissions from products

- Value engineering to redesign products with a lower carbon footprint

- Product lifecycle management, e.g. recycling, waste management

Our Sustainable Procurement Insights