Many decision-makers see big data and advanced analytics – in other words, automating the assessment and visualization of structured and unstructured data from internal and external data sources – as a key digitization task in procurement, along with process automation. In an age of hybrid procurement organizations, with value creation chains becoming increasingly networked, the ability to press a button and access the latest data that has been transparently prepared is a real advantage.

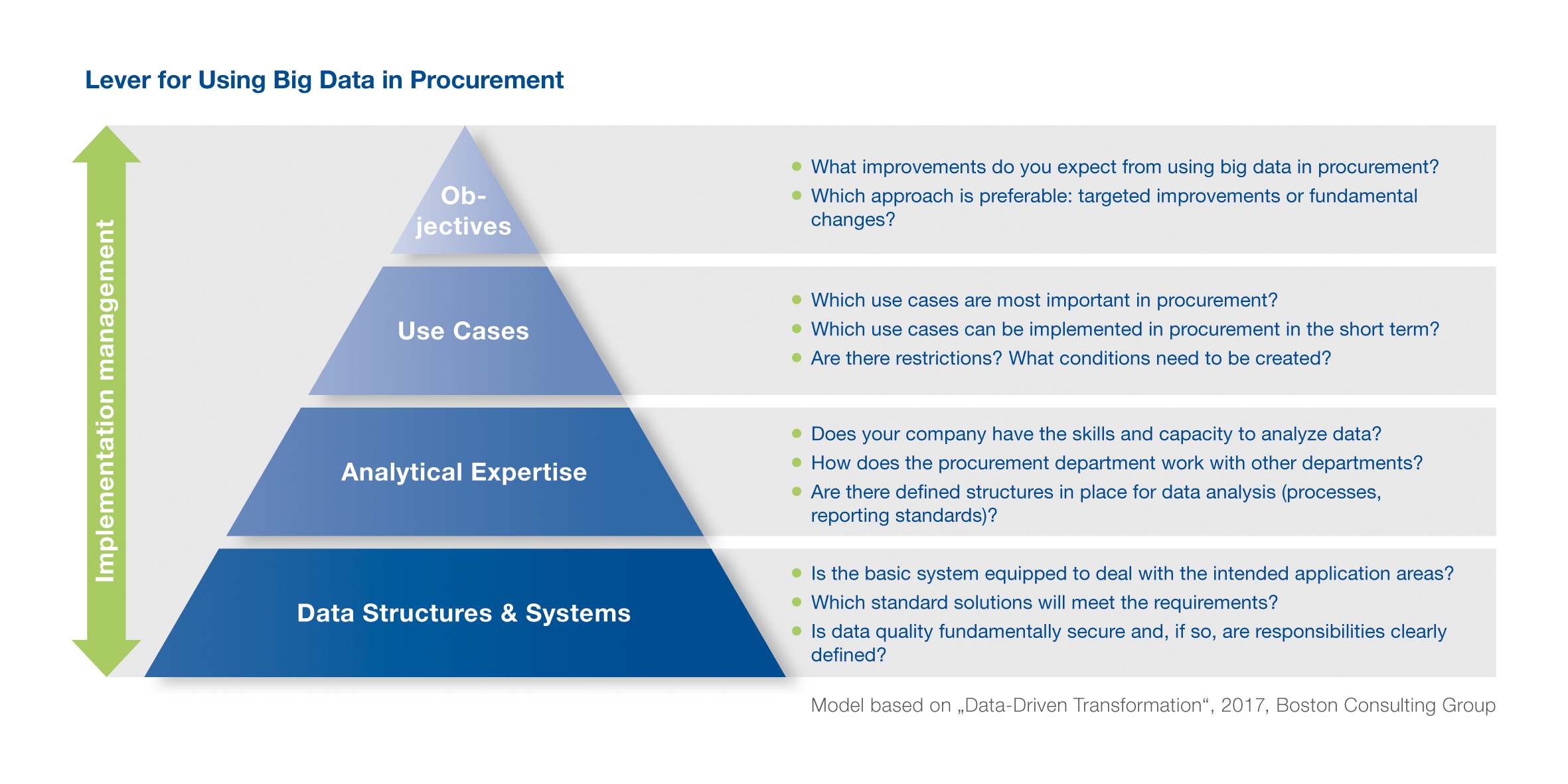

The problem is that many companies have neither developed a consistent analytics strategy nor defined any application areas and goals, even though this is vital for successfully employing new forecasting methods and platforms.

Incorporating big data analytics into procurement

Procurement is ideal for big data applications, as added value directly improves business performance, usually demonstrated in terms of savings and performance increases. Digital solutions are also already being used in many procurement departments; for example, to forecast demand or to request and evaluate tenders. In view of this, building skills in big data analytical is the next natural step to the digital transformation journey.

When using advanced analytics, understanding that data is linked and interpreted on the basis of an overarching model and that interfaces are actively controlled via application systems is crucial. Although data quality is a key factor, this is often where the need to catch up is greatest, since even structured data from ERP systems is not uniformly managed and is often poorly maintained by companies. That means decision-makers must make their staff aware of the need for a consistent approach when handling data. The good news is that big data analytics generally doesn’t require far-reaching changes to a company’s data structure.

From spend report to real-time supplier performance

The first place to start when using analytical tools is with classic procurement reporting. Merging ERP data forms the basis for spend reporting or determining average prices, tailoring the report function to exact user requirements. Self-service analytics is a model allowing users to access the information they need without involving the IT department, almost at the press of a button.

A more advanced way of using big data analytics to improve procurement can involve additional data sources. Expanding existing procurement and costs analyses by incorporating the latest raw material prices and exchange rates is a typical example of this, using both internal and external information. Publicly available price series – from stock markets, for example – can be included here.

Real-time applications represent yet another advancement and can be used to facilitate decision-making, with information being processed immediately. This allows buyers to detect changes quickly and react accordingly. A live dashboard to monitor suppliers can provide buyers with real time information about delivery performance. If a supplier is unlikely to be able to deliver the agreed quantities, the buyer can find out at an early stage, giving him the opportunity to procure the requirements elsewhere.

Other applications used to facilitate decision-making are built on this foundation, such as model-based forecasting. Existing cost breakdowns for industrial products can be used to forecast cost structure changes based on macroeconomic data and trend analyses, such as wage rises caused by changes to legislation or higher energy prices in procurement countries. Information for these kinds of findings could be obtained from various sources, including news portals, economic databases, and social media channels.

Add value with process automation and AI

The latest developments in robot process automation (RPA) and artificial intelligence (AI) are another important factor that has significantly improved analytical tools in recent years. Machine learning enables software to automatically derive recommendations from its analyses, which are then further validated each time feedback is given by procurement.

Internally available data can be linked to external data sources wherever there is an opportunity to add value, helping to structure procurement activities within an automated process. This means, for instance, that potential suppliers can automatically be contacted about requirements and with a request for quotation before an agreement expires. The system then captures, analyzes, and evaluates the supplier quotations. This information is used to submit the order under the most favorable conditions or to prepare a proposal for procurement staff. Automated solution concepts can also be designed for common problems such as returns or delivery delays.

Winning over both executives and staff

Generally speaking, implementing big data goals involves simultaneously expanding analysis expertise and system requirements, and will only succeed if all stakeholders are willing to cooperate. In other words, technical implementation involves not only the IT department, but also the department with responsibility for that specific area, so they should be directly involved in validating and developing the implementation of pilot projects and the assessment of potential applications.

The process from developing the initial integration of a spend analytics tool through to the automated data-driven selection of suppliers requires switching from an analog approach to a data-driven organization and gradually building confidence in the automated handling of procurement tasks. Of course, this won’t happen overnight, so the whole team needs to be brought up to date and engaged in the process.

Accepting new solutions that make decision-making and automation easier should be encouraged during the course of a scalable pilot application. Tasks that offer a quick return on investment and are highly visible throughout the company are ideal. As is usual in agile project management, pilots are progressed in targeted sprints that test both the solution’s functionality and users’ skills.

Effective procurement pilot projects will help to convince decision-makers and staff of the advantages of the digital transformation. Short-term savings and improved performance indicators secure buy-in from top management and wider acceptance of expanding big data solutions to other areas within the company.

Companies that can successfully capture increasing amounts of data and turn them into forecasts and support for actions are primed to benefit from an optimal foundation for future decisions. However, implementing suitable IT systems is an essential step.

Find out more here about how to find the appropriate digital tool for advanced analytics and other procurement fields.

Definition:

Big data analytics refers to the study of information with a varying degree of quality and in various formats that is subject to rapid change and is generated on an unprecedented scale. Patterns in supply requirements, price/performance correlations, market trends, customer preferences, and other economically relevant information are updated in ever-shorter cycles and are available as a tool and foundation for making decisions in procurement. Self-generated data (e.g. expenditure for a range of purchases) can also be included along with external data (e.g. commodity indices).