PROCUREMENT: LET’S GET REAL!

Our expert Kiren on decarbonisation

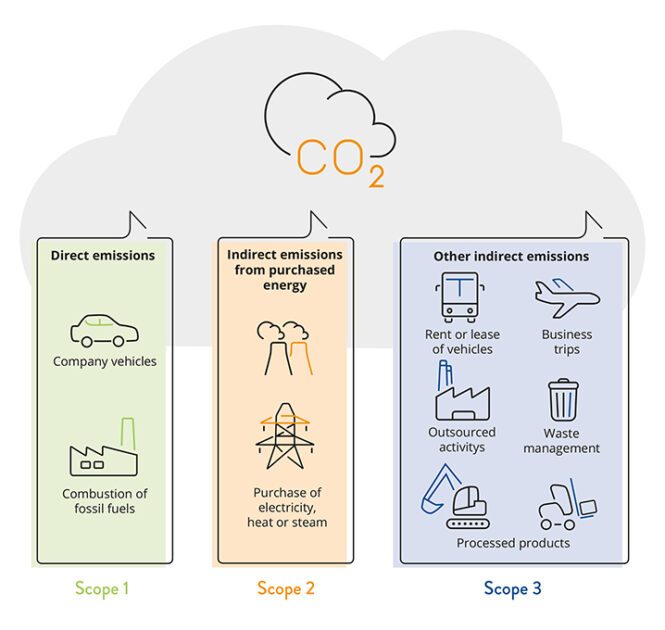

On the topic of decarbonization, it should first be defined which section is meant in terms of the generation of emissions. Divide into three sections:

- Scope 1: direct emissions from the company’s own production

- Scope 2: indirect emissions related to the purchasing of electricity and air conditioning of the company’s buildings

- Scope 3: all other emissions that arise in the company’s value chain, caused by suppliers, services or logistics

While the amount of Scope 1 and Scope 2 emissions is relatively easy to determine and within a company’s direct sphere of influence, Scope 3 emissions lack both transparency and direct access. Procurement, with its direct contacts to suppliers and service providers, plays a key role in mitigating Scope 3 emissions. We recommend a three-tiered approach.

Procurement should take a leading role in the dialogue on decarbonization.

The most important task for the procurement organisation is the dialogue with suppliers. Each category manager has – or at least should have – a precise overview of the suppliers in their category. The category managers evaluate criteria such as quality and delivery reliability as well as compliance with the corporate strategy.

Sustainability criteria, on the other hand, have so far rarely been part of this evaluation. By taking so-called ESG (environmental, social, governance) criteria into account, the supplier landscape can be opened up to providers who can really change your company’s emissions. Decarbonization is a shared responsibility across the value chain and it is therefore essential to work with strategic suppliers on decarbonization. Even though your current suppliers may not yet be able to meet the new requirements in the short term, cooperation can create new, CO²-reducing or even CO²-neutral solutions.

Procurement should include decarbonization in supplier assessments

When evaluating products and services, procurement considers several dimensions such as price, quality or payment terms. ESG criteria can be easily integrated here. In addition, procurement can ensure that clauses on sustainability and alignment of Scope 3 targets between partners are included in contracts.

Your procurement should derive the targets from the overall corporate strategy. Sustainability targets should also be included in incentives: If decarbonization is part of the KPIs for employees, credibility and engagement will increase.

Procurement sets the decarbonization roadmap

Since procurement is company-wide, it is the natural point of contact to develop a decarbonization roadmap. The purchasing department analyses and decides in which order categories and suppliers face the issue of decarbonization. In addition, procurement can learn through dialogue with suppliers: it is possible that some of your suppliers are already a step ahead of you on the road to carbon neutrality or are pursuing approaches that are also helpful for your company.

How to get started

Decarbonization is a process that will take several years. For good reason, the European Union has set a relatively large timeframe for achieving full carbon neutrality. However, we are convinced that it is necessary to start early, even if all solutions are not yet obvious.

Talk to your suppliers, set targets and start! It is important to be willing to learn and open to new solutions – both your own and those of customers, suppliers and competitors.

We recommend a practical approach to ensure a smooth start:

- Evaluate the maturity of sustainability in your procurement

- Define a decarbonization roadmap together with procurement and determine which categories and suppliers to target and when

- Define targets together with top management and the CPO

- Introduce tools, processes and policies to align supplier management with sustainability

- Introduce a calculation method for emissions

- Integrate ESG criteria with a focus on decarbonization into the procurement process, including the necessary tools and guidelines

- Make sure that all procurement officers have appropriate KPIs